Camera specifications

| Sensor | Tri-linear CMOS color line sensor |

| Pixel size | 5.6 µm × 5.6 µm |

| Line spacing | 5.6 µm between R-G & G-B |

| Spectral sensitivity | 360 nm – 960 nm |

| Resolution | 10240 pixels × 3 lines |

| Video output | Single/Dual 10GigE, GigE Vision® 2.0 compliant |

| Data format | 3 × 8/10/12 Bit color or 1 × 8/10/12 Bit mono |

| Trigger Mode | Frame Start / Frame Active / Line Start External trigger Line trigger / Encoder and Frame trigger |

| Video output port | 2 × SFP+ |

| Interface position | X |

| Digital I/O port | External I/O (15 pin HD D-Sub, fem.) |

| Power supply | 6 pin Hirose, male 12 V – 24 V DC ± 10 %; 1 A @ 24 V |

| Debugging port | USB 2.0 (Micro USB) |

| Lens mount / adapter | M72 × 0.75 mm / F-mount |

| Housing dimensions | 102 mm × 76 mm × 82 mm (W × H × D) |

| Weight | 0.9 kg |

| Temperature during operation | 0 °C – 60 °C; 32 °F – 140 °F |

| Humidity during operation | 20 % – 85 % relative air humidity, non condensing |

| Temperature during transport and storage | -20 °C – +85 °C; -4 °F – +185 °F |

| Protection category | IP50 |

| Certifications | CE, RoHS |

| General ambient conditions | |

| Transport | IEC 721-3-3:IE33 |

| Operation | IEC 721-3-3:IE21 |

| Storage | IEC 721-3-3:IE11 |

Line scan sensor

Sensor line spacing

Sensor line spacingSensor pixel arrangement

Spectral sensitivity

Measured relative spectral sensitivity of the 10k and 15k sensor - mono

Measured relative spectral sensitivity of the 10k and 15k sensor - monoSensor alignment and orientation

| Feature | Value |

|---|---|

| First pixel | Left side |

| Sensor position alignment | X: < ± 100 µm Y: < ± 100 µm Y: < ± 100 µm |

| Sensor rotation alignment | Y: < ± 0.1° Z: < ± 0.1° |

| Planarity of the sensor interface | < ± 0.5 µm |

| Sensor window thickness | 1.1 mm |

| Refraction index | 1.5 |

| Optical path extension | 0.55 mm |

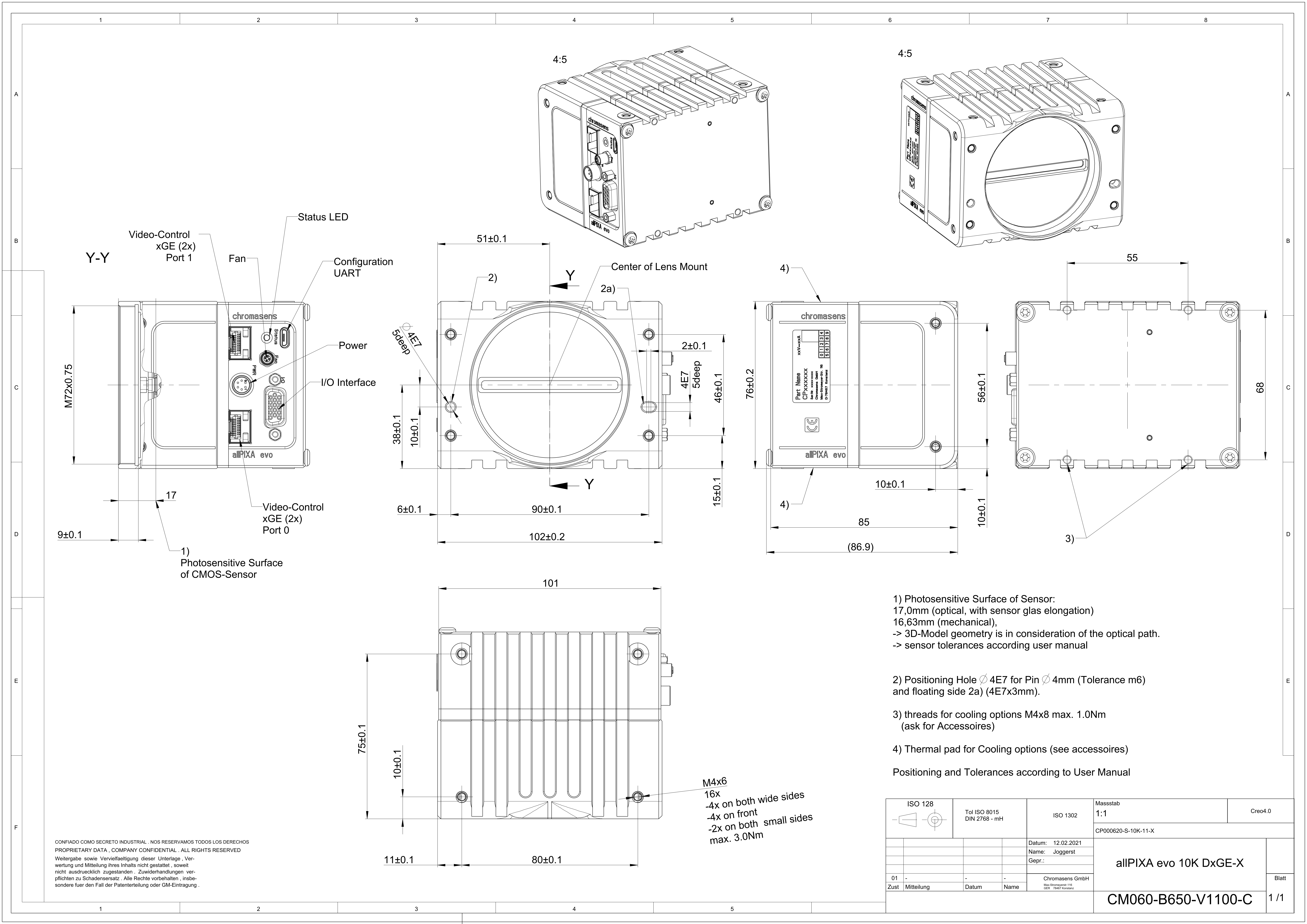

Mechanical dimensions

Dimensional drawing of the allPIXA evo 10k DXGE – interface position X

Download as pdf-file

Interface specification

| |||

| 1 | Video output SFP+ port 1 (10GigE) | 2 | Status LED |

| 3 | Debugging port | 4 | Connector for additional fan |

| 5 | Power supply | 6 | Digital I/O port |

| 7 | Video output SFP+ port 2 (10GigE) | ||

Line rate

| Configuration | Single 10 GigE | Dual 10 GigE |

|---|---|---|

| RGB 8: 10,240 × 3 pixel | 38.5 kHz | 68.4 kHz |

| RGB 10: 10,240 × 3 pixel | 19.3 kHz | 34.7 kHz |

| RGB 12: 10,240 × 3 pixel | 19.3 kHz | 37.7 kHz |

| Mono 8: 10,240 × 1 pixel | 68.4 kHz | 68.4 kHz |

| Mono 10: 10,240 × 1 pixel | 57.4 kHz | 68.4 kHz |

| Mono 12: 10,240 × 1 pixel | 57.4 kHz | 68.4 kHz |

Power supply

The following connector is required for the power supply cable:

- Manufacturer: Hirose

- Article no.: HR10A-7P-6S female

| Pin | Description | |

|---|---|---|

Pin allocation of the power supply port Pin allocation of the power supply port

| 1 | Power +24 V |

| 2 | Power +24 V | |

| 3 | Not connected | |

| 4 | Not connected | |

| 5 | Ground | |

| 6 | Ground |

Digital I/O port

NOTE

Ensure a proper GND connection of the digital camera I/O port and your trigger.

The following connector is required for the digital I/O port:

- 15-pin HD D-Sub (male)

| Pin | GenICam | Signal | Level | In/Out | Example/Remark |

|---|---|---|---|---|---|

| 1 | Line 1 | Enc0_InP (+) | RS 422 | Differential input | Encoder0 or LineTrigger |

| 2 | Line 2 | Enc1_InP (+) | RS 422 | Differential input | Encoder1 or Frametrigger |

| 3 | Line 3 | IO_0P | LVCMOS | Input | single-ended |

| 4 | - | RT | RS 485 | - | - |

| 5 | Line 5 | IO_2P | LVCMOS | Out | LED-Out1 |

| 6 | Line 1 | Enc0_InN (-) | RS 422 | Differential input | Encoder0 |

| 7 | Line 2 | Enc1_InN (-) | RS 422 | Differential input | Encoder1 |

| 8 | Line 4 | IO_1N | LVCMOS | Input single-ended | Trigger or Master-Slave Cascaded |

| 9 | - | RTN | RS 485 | Out | To LightController XLC4 |

| 10 | Line 6 | IO_3 | LVCMOS | Out | LED-Out2 |

| 11 | - | GND | - | GND | - |

| 12 | Line 7 | IO_4_SDA | LVCMOS | Out | LED-Out3 |

| 13 | - | GND | GND | - | - |

| 14 | Line 9 | Master/Slave | LVCMOS | Bi-directional | Master/Slave |

| 15 | Line 8 | IO_5_SCL | LVCMOS | Out | LED-Out4 |

LVCMOS and RS422 levels

| I/O standard | V_IL | V_IH | V_OL | V_OH | ||

|---|---|---|---|---|---|---|

| V_min | V_max | V_min | V_max | V_max | V_min | |

| LVCMOS | –0.5 | 0.7 | 1.7 | 3.6 | 0.4 | 2.1 |

| RS422 | –6 | 0.8 | 2 | 6 | - | - |

| NOTICE |

| Non compliance may cause irreparable damages to the device. | |

| The maximum input level of the LVCMOS is 3.6 V. Use a level converter if necessary (e.g. 74 LVC14). |

Micro USB

The Micro-USB connection is currently used for debugging information.

LED status indicator

| Color code | Behaviour | Description |

|---|---|---|

| Off | No power supply or the input voltage is out of range. |

| Blue continuous | The device is OK and provides image data. Between image gaps the LED is off. |

| Green continuous | The device is in power-up mode. |

| Green blinking | The device is OK and ready. |

| Yellow continuous | Warning-state: The device is operational. |

| Red continuous | Error-state: The device is not operational. |